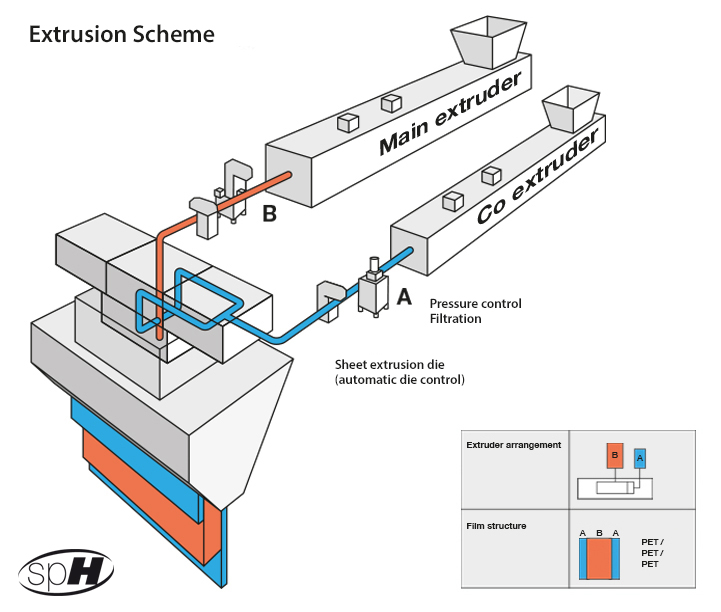

Before arriving at the extruders (main extruder 80 %, co-extruder 20 %), the resin passes through a metal separator. Afterwards, the resin is melted down and homogenised in the extruder cylinders together with the additional elements of the composition by pressure and temperature imposed thereon. As a matter of principle, the colour batches are incorporated via the main extruder and the additives such as anti-block additives via the co-extruder. Two decontamination stations in the main and the co-extruder ensure additional safety. Molten mass pumps provide for a constant pressure curve. After being filtered in automatic reversible flow filters, the molten mass flows coming from the main and the co-extruder are merged in a laminating block and thereby constitute the three layers of the PET film in the sheet die.

English

English Deutsch

Deutsch Français

Français