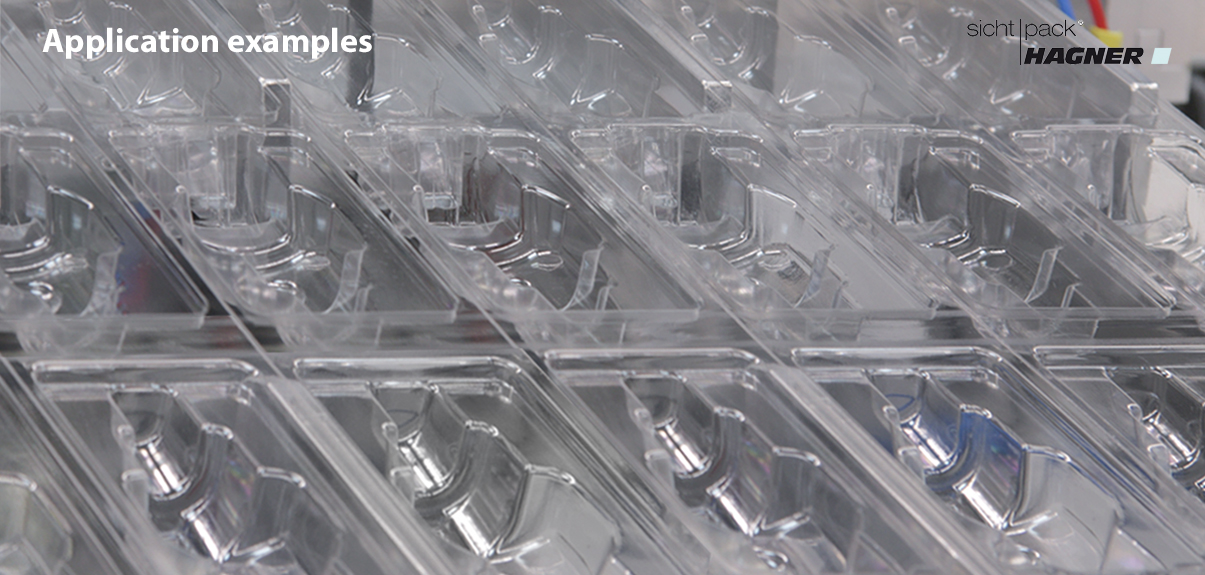

SICHT-PACK HAGNER GMBHTranslation:

As of end of the year own PETP film manufacturing "Constructive environmental consciousness" Film sales also to third parties

What set the cat among the pigeons at the Düsseldorf "Interpack 87" in the PVC packaging industry, has been put in concrete form in the meanwhile: One of the German leaders in the field of PVC transparent packages, sicht-pack Hagner GmbH (D-7295 Dornstetten/Hallwangen)

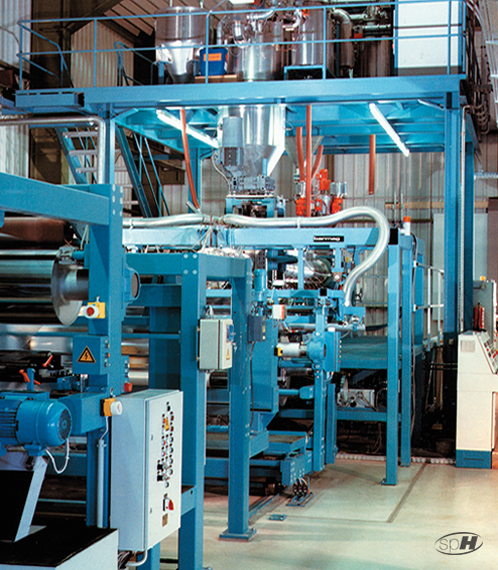

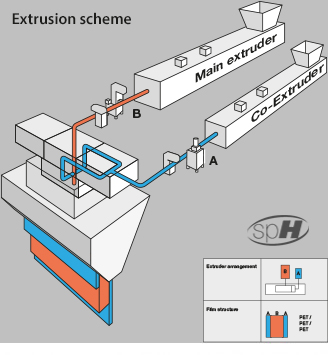

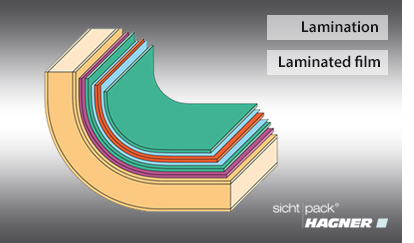

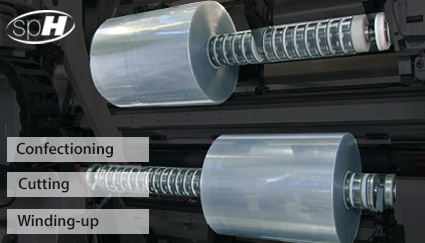

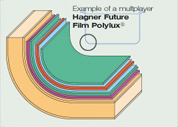

is going to start its own manufacturing of polyester (PETP) films by the end of the year. At present, a new three-storey operational building having an overall surface of appr. 3,800 sqms is erected. Here, a complete extrusion line and an ultra-modern recycling installation will be installed

from end of September. Supplier of the extrusion line is the Barmag AG (Leverkusener Str. 65, D-5630 Remscheid-Lennep) belonging to the Enka group. The dryers come from Somos, the recycling blade granulators from Condux.

sicht-pack Hagner (appr. 100 employees, branch in Canada) is the first

German midsize processor of rigid PVC films who gets into the PETP film manufacturing with a considerable investment of some millions. Background: On account of the increasing "discussion about PVC " Hagner didn’t see any other possibility already a long time ago than being on the

lookout for substitutional films. The hitherto existing suppliers of films – the well-known German manufacturers of rigid PVC films – were requested by Hagner to include PETP in their array of products. But their backing was missing, "since we were clearly told that they had written PVC

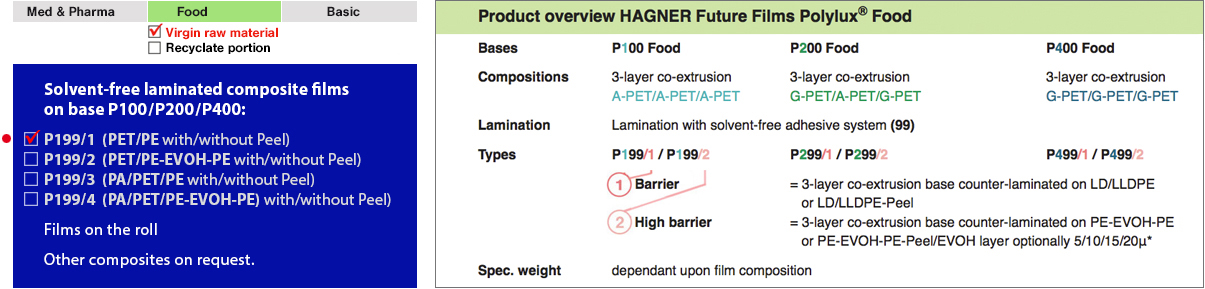

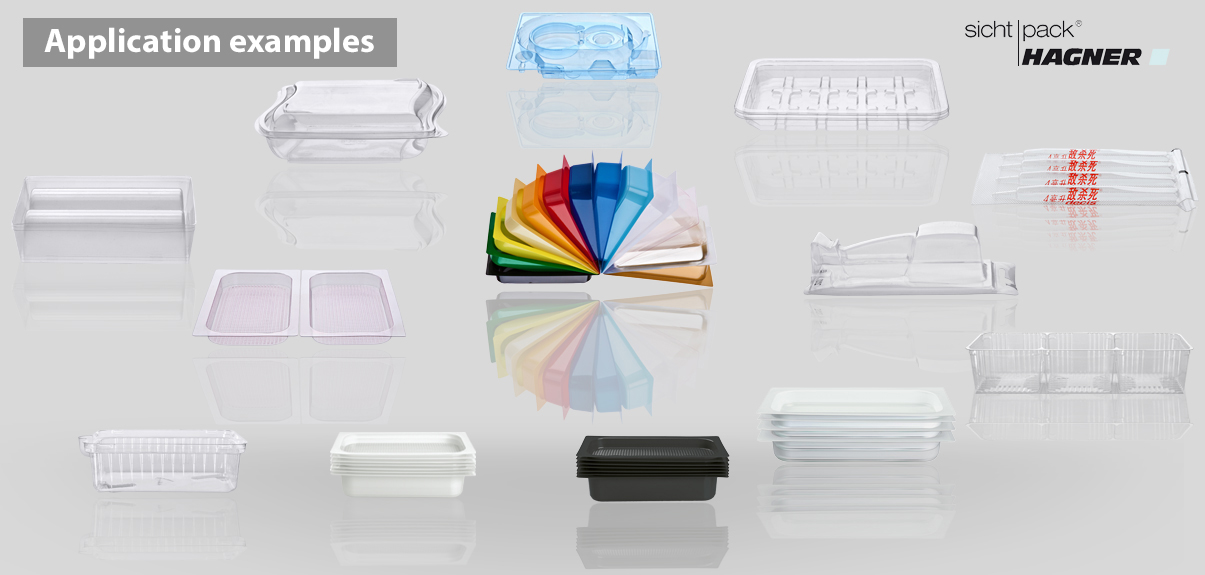

across their banner ". Hagner, therefore, took the bull by the horns and decided to start his own manufacturing of PETP films. The new "SP films" are, however, not only produced for his own installation consumption, but are also to be supplied to other processors of films.

If required, Hagner is going to install his second extrusion line

The marketing of the "SP films" made of PETP films is run under the header "environmentally friendly" ("Constructive environmental consciousness with the same packaging convenience "),

indeed without mentioning PVC directly. By doing so, any legal actions are – cleverly – avoided which might be taken by the PVC lobby who didn’t always pull no punches in the past when fighting against comparable marketing cases. Chief executive Hans Hagner is quite relaxed when expecting

such steps. In an interview with KUNSTSTOFF INFORMATION during the last week, he also demonstrated strength in other respects: In the near future he is expecting other midsize packaging manufacturers to turn towards PETP and to the corresponding manufacturing of films. Hagner: "PETP

is the basic material of the future for our industrial sector. And competition is good for business "

KI-SERVICE: Advertising folders "SP film – The step forward as regards environment ": KI-Nr. 24345- Basic folder"All packages now available made out of environmentally

friendly PETP film, too " (with folding box sample out of PETP film)

24346 – Company portrait brochure on the occasion of the company being in existence for 25 years 1986: KI-Nr. 24347.

10.09.1987 KI 845 [43542]

English

English Deutsch

Deutsch Français

Français