SICHT-PACK HAGNER GMBHTranslation:

Expert for rigid PET films is 50 years old / About folding boxes and highly-efficient film manufacturing

Did Hans Hagner have an uneasy sense in the year 1961 of the dimensions to which the enterprise established by him at that time would increase? The start-up meant folding transparent boxes in a back room which Hagner used for distributing goods in the Swabian surroundings. Today, after 50 years, sicht-pack Hagner

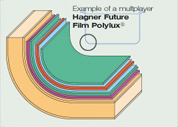

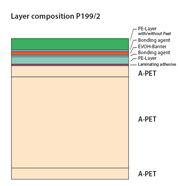

GmbH (D-72280 Dornstetten; www.sicht-pack-hagner.de) is one of the leading European manufacturers of rigid PET films for thermoforming with more than 200 employees, a sales volume of 100 m EUR and flexible production facilities

of about 85,000 tons per year.

In 50 years from folding boxes to the leading PET film plant in Europe: The contemporary plant of sicht-pack Hagner in Dornstetten

In 50 years from folding boxes to the leading PET film plant in Europe: The contemporary plant of sicht-pack Hagner in Dornstetten

(Foto: sicht-pack Hagner)In between there are several inventions and innovations, soft creases for folding boxes or transparent circular boxes, for instance, as well as in 1987, as a German pioneering enterprise, the entry into manufacturing PET films

which was not

undisputable at that time – see KIWeb of 10.09.1987. Then years later, Hans Hagner, who lost his life in a plane-crash in 2002, assigned the corporate management to his son Heinrich Hagner who is still responsible for the fortunes of the family-owned enterprise in Dornstetten. By the end of the 90s, sicht-pack

Hagner disassociated from manufacturing packages in order to focus on producing rigid PET films as packaging material - see KIWeb of

03.05.1999.

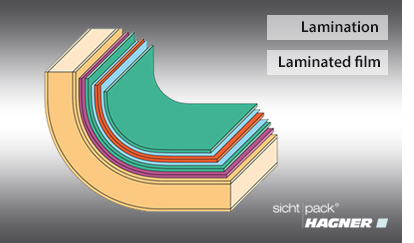

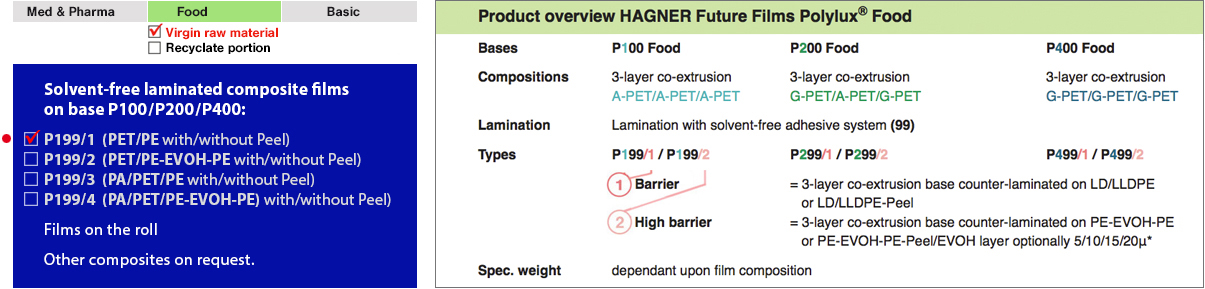

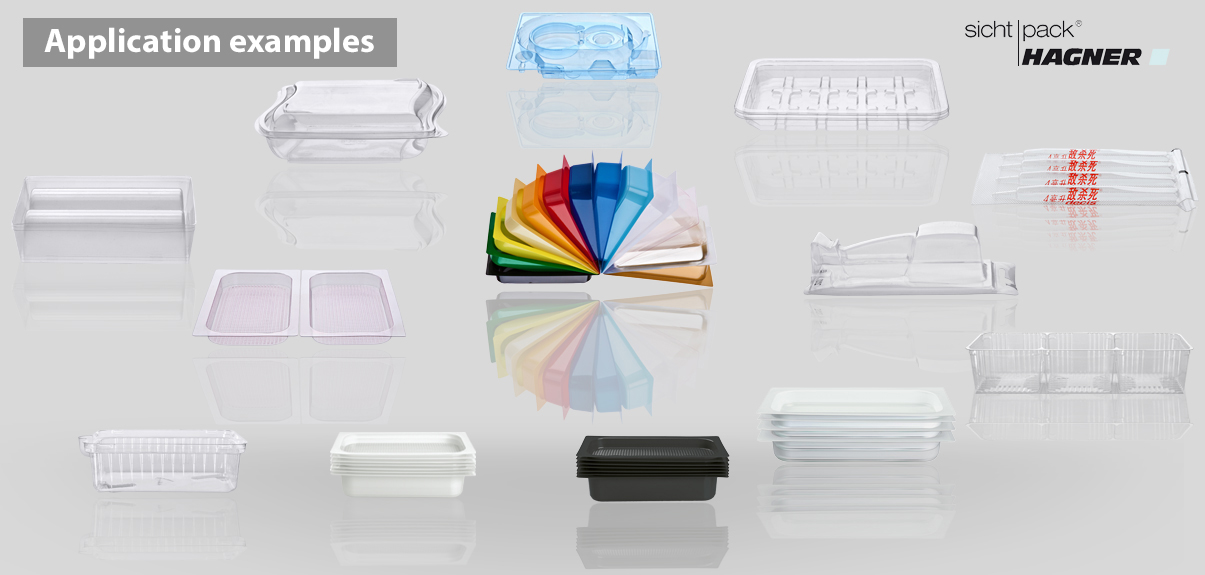

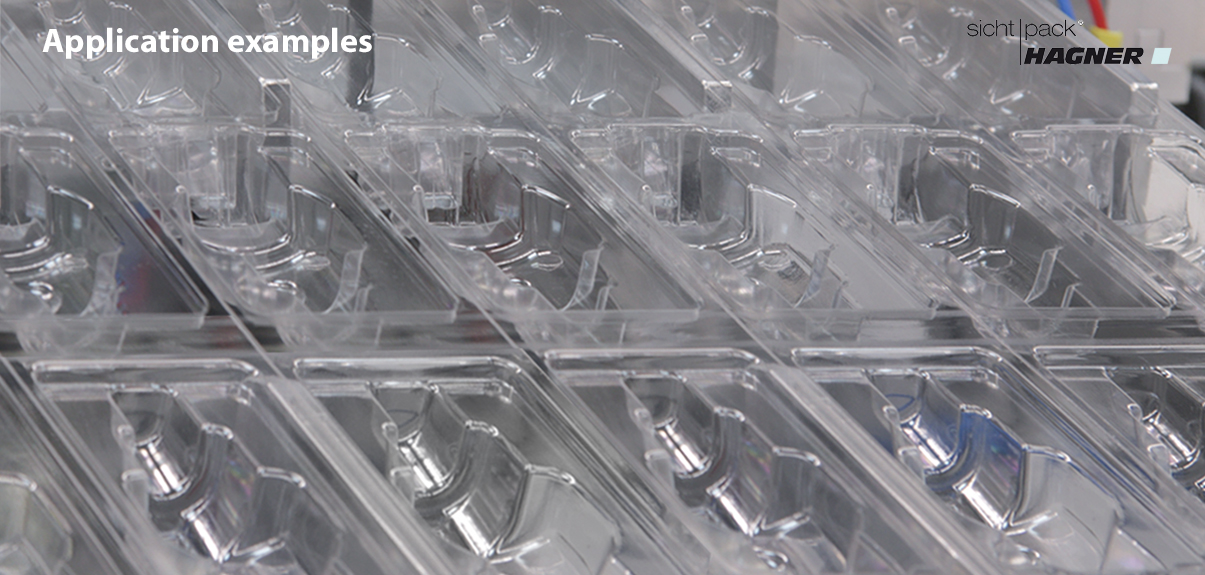

As the main market for the transparent PET films, the packaging of

food stuffs

has taken shape going from strength to strength.

Since the contact with food stuffs entails a particularly high sensitivity for the packaging materials, the enterprise

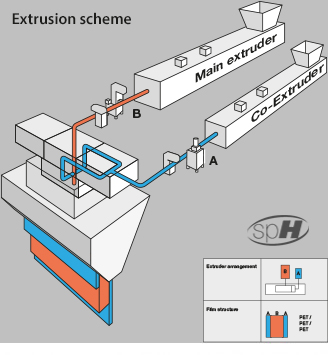

was intensely engaged in this matter during the last ten years and matched the whole production with the basic conditions of this customer industry. Who comes to Dornstetten today sees an elaborate, highly-efficient flexible film manufacturing plant

though having a high compactness which may claim to be able to set standards in many respects.

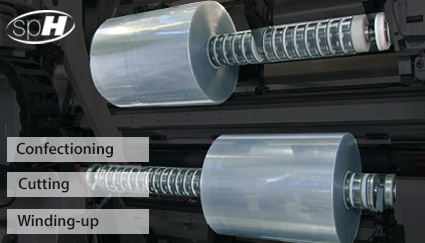

The individual production lines were developed with the leading collaboration of Hagner himself and offer exceptionally high load capacities providing at the

same time very quick and easy change facilities what likewise allows smaller specific charges. Unusual for a film manufacturer is particularly the nearby clean-room production. The whole

production area can only be entered via disinfecting double-door systems and with protective clothing. The whole material flow is highly automated. This particularly applies both for the supply side where the work is done by means of a pneumatic insulated feeding system out of the silos

and for the production and delivery area where the

hygienically packaged goods are brought to a nearby external warehouse.

The complete production and operation control is continuously monitored by a SAP system. The comprehensive quality management is invariably documented so that all failures can be detected

and correlated accurately to the millimetre and the second in the manufacturing process.

“We have looked around at our customers and introduced their conditions in our

plant. This is the only way to be an adequate member of this highly sensitive delivery chain”, describes Heinrich Hagner the

motivation for the profound conversion in conjunction with high investment in his interview with KI. “Any such

way of production can only be carried through for all products”, so continues Hagner. The enterprise that has been correspondingly

certified in many cases consequently offers all customers of other application fields the same quality.

11.02.2011 KI 2044 [218049-0]

English

English Deutsch

Deutsch Français

Français