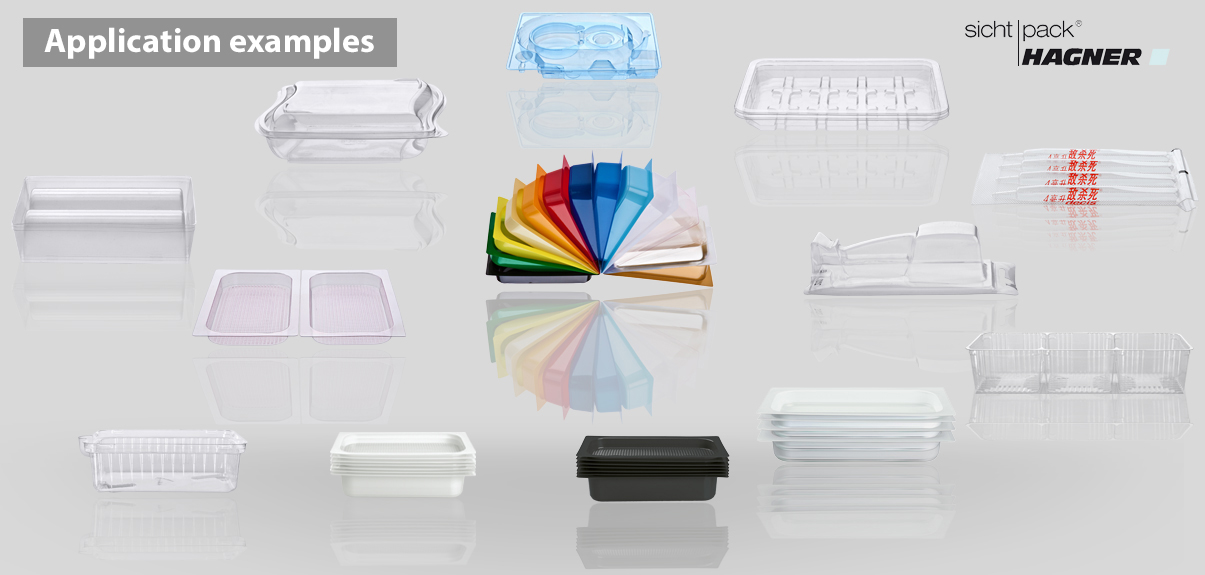

sicht-pack HAGNER set the course to manufacture transparent packages and thermoformed parts out of PET already in the middle of the 80s.

At that time, sicht-pack counted as one of the most important manufacturers of transparent packages in Germany.

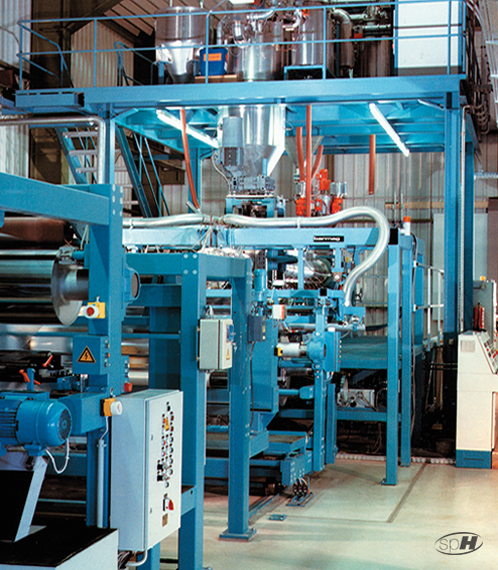

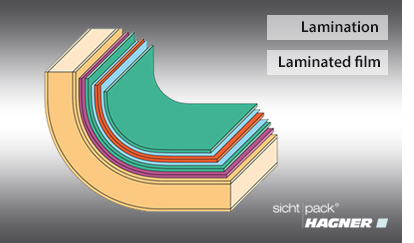

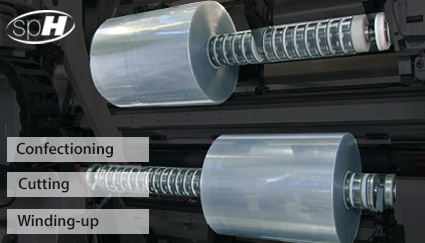

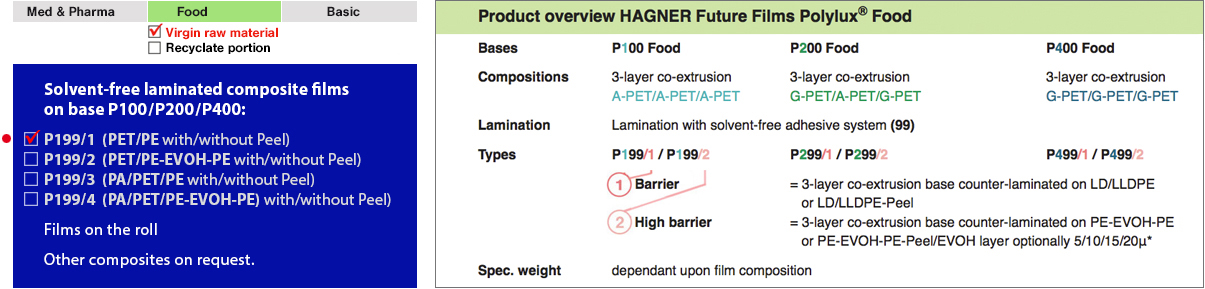

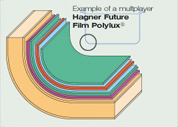

The knowledge and the experience of transparent and thermoformed packages directly contributed to the development of PET films. Meeting a good response to their PET packages, sicht-pack started marketing PET films. In 1991, the first laminating installation for the manufacturing of composite films was put into operation. In 1997, Hans Hagner handed over the management to his son Heinrich Hagner.

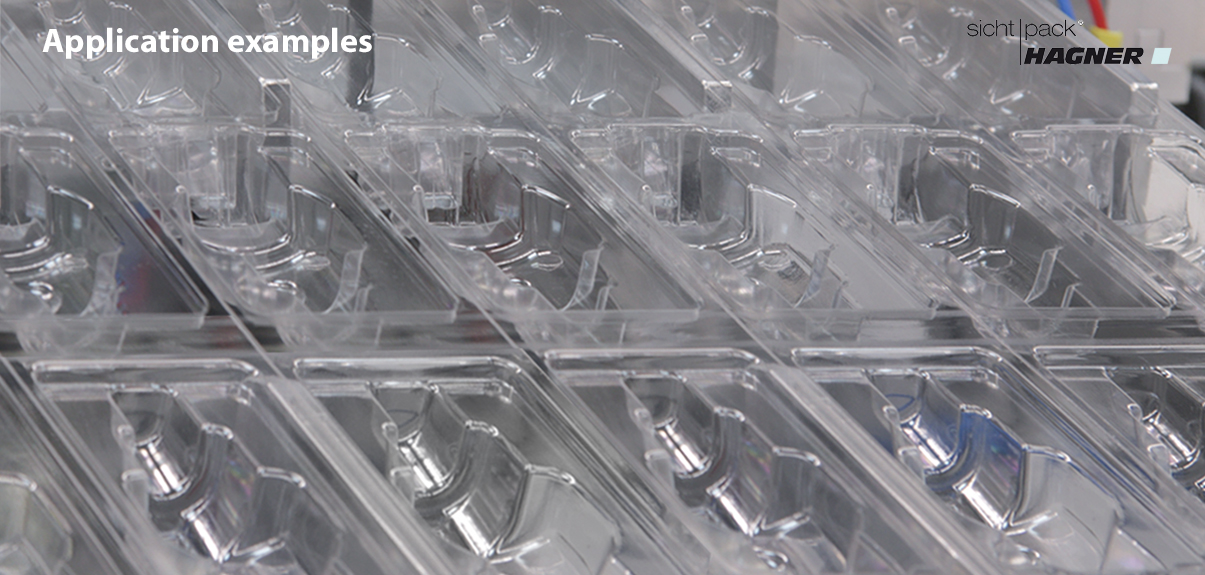

On account of the enormous demand for PET films, the enterprise was reoriented. sicht-pack HAGNER concentrated on amplifying its capacities of manufacturing films on the one hand, and on the large-scale production of transparent packages on the other hand so that the enterprise left the fields of folding boxes, circular boxes and self-locking cases.

At that time, sicht-pack counted as one of the most important manufacturers of transparent packages in Germany.

The knowledge and the experience of transparent and thermoformed packages directly contributed to the development of PET films. Meeting a good response to their PET packages, sicht-pack started marketing PET films. In 1991, the first laminating installation for the manufacturing of composite films was put into operation. In 1997, Hans Hagner handed over the management to his son Heinrich Hagner.

On account of the enormous demand for PET films, the enterprise was reoriented. sicht-pack HAGNER concentrated on amplifying its capacities of manufacturing films on the one hand, and on the large-scale production of transparent packages on the other hand so that the enterprise left the fields of folding boxes, circular boxes and self-locking cases.

English

English Deutsch

Deutsch Français

Français